Cormorant

CORMORANT

Menu

Sustainable general aviation – a catalyst for remoter communities’ development

Cormorant is an adaptable, reconfigurable general aviation solution with practical application across several market segments, e.g., air taxi, tourist flights, light cargo, medevac. Here we consider our approach to sustainability, and how, if the political will is present, solutions such as Cormorant are key to sustaining, if not reinvigorating, remoter communities. For these more economically marginal societies, practical environmentally-appropriate infrastructure investment will be key to their social cohesion and prosperity.

Electric general aviation solutions will provide the first commercially available green aircraft solutions to reach the market. At Cormorant, it’s not just about producing a zero-CO2 emission aircraft – sustainability to us is more than that. Through setting sustainability as a goal from the outset, besides obviously producing a desirable, adaptable, reconfigurable aviation transport solution, we believe that Cormorant can contribute, albeit in a small part, to making the world a better place. Here we summarize how we see sustainability enriching both the communities served by our transport solution together with Cormorant’s stakeholder community, in terms of:

Achieving zero-emission targets is about ‘deliverability,’ which we consider in this context to be making an effective, usable, certified, aviation transport solution that is ‘deliverable’ within the shortest timeframe. Adding unnecessary layers of complexity to concepts, particularly if they are technologically innovative, reduces speedy deliverability by encountering multiple, unnecessary bottlenecks, particularly in the regulatory certification process. Given the climate emergency,[3] speed is of the essence in delivering, viable sustainable solutions; now is perhaps not the time to be berating regulatory agencies charged with certifying these – particularly when their cultures are conservative, focused on incrementality, and have a justifiable preoccupation with safety.

We consider that incremental innovation and the use of proven, certified solutions where practical is the quickest and most responsible route to delivering green general aviation solutions. This leaves the regulatory framework relatively clear for the process of approval of zero-emission powertrains that are core to sustainable aviation solutions. We would contend that now is not the time to be grandstanding and, perhaps, massaging visionary egos by offering technologically overly radical, ‘sexy’ (in the marketing, presentational sense) projects to divert investors’ funds and regulators’ limited resources from achieving commercial, sustainable aviation solutions as soon as possible. The urgency of the climate emergency suggests that diversions from achieving the most demonstrably practical solutions are irresponsible; it “is a race we are losing, but it is a race we can win,”[4] but only through concerted focused effort and the avoidance of distractions.

When a different technology is applied to meeting an existing market need, as is the case for zero-emission powertrains in aviation transport applications, there is a temptation to revolutionize rather than incrementally improve solutions.

Within a highly regulated sector, such as are aviation design, manufacturing, maintenance, training and operation, revolutionary solutions are anathema – particularly when ‘revolution’ occurs at multiple levels in offering an ‘exciting,’ exotic, new, integrated transport architecture. It is difficult enough for the certification authorities to approve new, “novel” powertrain solutions promptly and effectively for safe, commercial operation without adding layers of additional complication such as distributed power systems, autonomous flight, new air traffic control corridors, systems for urban aviation solutions etc.

Some exotic e-aviation solutions may well yield results, and we wish them and their investors well, for many however the quotation “like Saturn, the Revolution devours its children”[5] is likely to prove appropriate. ‘Exciting,’ new, overly revolutionary solutions can create a vortex of hubris for those vested in the project together with investors convinced of that project’s over-promises. Nemesis, in the form of those investors’ realization of under-delivery within their return timeframes, may unfortunately come all too swiftly.

Cormorant’s approach does not set out to be revolutionary. The use a zero-CO2 emission powertrain is the key technological step-change required to meet climate change limiting goals for aircraft operation, further use of ‘novel’ technologies elsewhere in the design serve only to frustrate and lengthen the certification process. Flexibility, both in terms of Cormorant’s utility for operators, and in its actual design, are central to offering a robust, multi-role, water- or land-surface operational aircraft that meets our original mission statement. Where a ‘revolutionary’ introduction of novel technology is required, i.e. in the design and installation of an electric powertrain, then our risk-minimizing, deferred strategic decision-making approach is a core management concept to keep our project focused and on-track.

Beyond this:

We see Innovation not ‘total revolution’ as the most effective and efficient way to deliver a practical, robust, zero-emission aviation solution that meets our mission statement values within the shortest practical timeframe. The communities and stakeholders that rely on zero-emission transportation solutions to combat climate change, such as that which Cormorant offers, are depending on timely delivery – solution providers, such as us, cannot afford to disappoint.

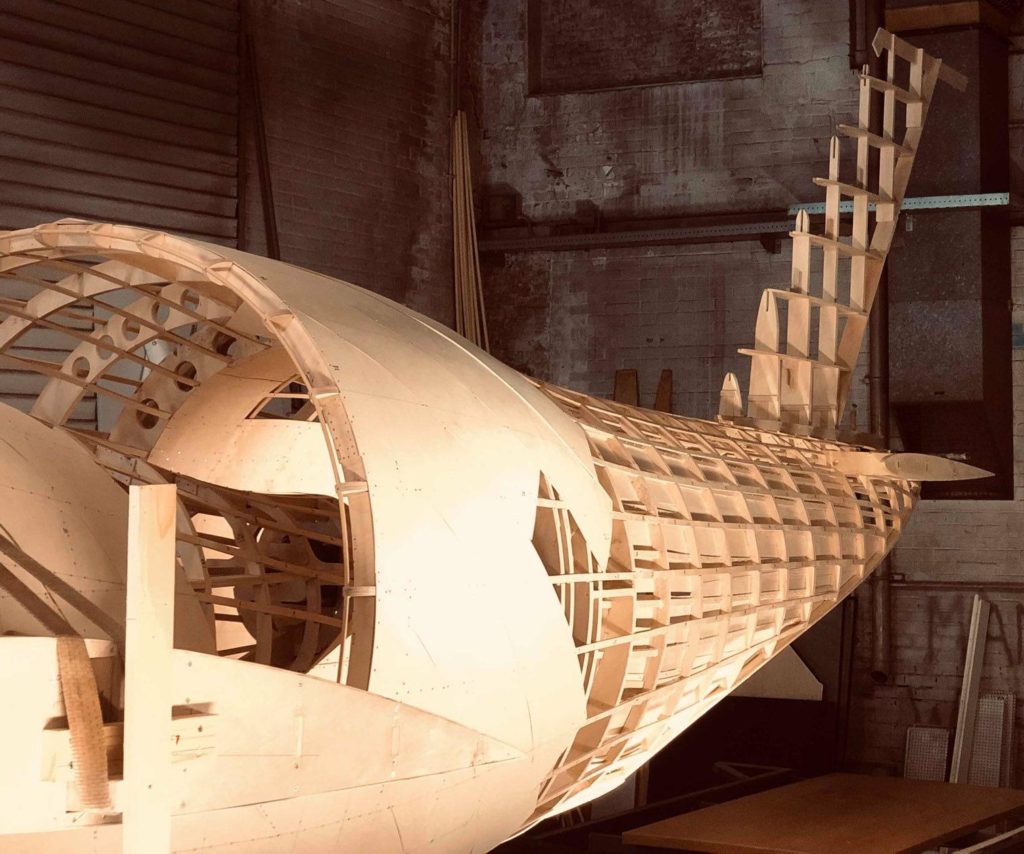

A significant contribution to sustainable manufacturing is Cormorant’s use of ecologically grown and harvested Sitka spruce as its core airframe material. A timber with an illustrious aviation heritage, Sitka spruce was a key structural component in, amongst others, the famous de Havilland Mosquito multirole combat aircraft, where the use of timber construction to facilitate “speed of prototyping, rapid development, minimization of jig-building time, and [subsequent] employment of a separate category of workforce”[6] hold true for Cormorant today.

Managed, sustainable cultivation and harvesting of this timber raw material occurs in several locations, including NW North America,[7] where Sitka spruce in endemic, and in northern Europe.[8]

Whilst the use of timber as a principal raw material in Cormorant’s airframe does not confer circularity per se, the use of such sustainable grown, harvested, and processed material combined with a circular philosophy applied to other components (i.e., within the aircraft’s powertrain, avionics, and other systems) results in a minimalist approach to the environmental impact of manufacturing. We shall not only produce an operationally zero-emission aircraft but will also aim to leave the smallest imprint practically possible.

This is rather a verbose way of saying that we believe, where feasible and practical, the benefits of a successful project should be distributed fairly amongst its stakeholders. For example, if timber raw material is produced on the lands of an indigenous community, then thoughtful consideration should be focused on adding value within that supplier stakeholder group, e.g., through further processing of raw materials and / or sub-contract the manufacturing of components.

We do not believe that localizing value-added is altruism for its own sake. Rather, it is a key component of a broader sustainable philosophy. Enhanced involvement of stakeholders, particularly suppliers in vulnerable or often-bypassed communities, can help their economic empowerment and contribute to their social sustainability.

Localization of value-added, as a concept, also feeds into the concept of distributed manufacturing.

Such a design and manufacturing process enables aircraft production to be, within reason, ‘distributed.’ Where volumes justify establishment, production sites could be located to serve key geographic market areas to perform aircraft assembly and serve distribution networks for finished aircraft, spare parts, and equipment more locally.

Due to poor infrastructure, particularly poor transport infrastructure, remoter communities can often suffer from selective depopulation of their younger inhabitants such that their demographics become increasingly elderly to the point of economic and social non-sustainability. Social infrastructure can easily degrade over time: schools may close due to there being insufficient pupils or professional staff proving difficult to recruit; medical facilities may also relocate to centers of higher population density; traditional businesses may become unviable and close; and / or second- holiday-home ownership from wealthy outsiders, attracted to the remoteness, may perversely inflate housing prices making them unaffordable for those ‘locals’ who wish to remain. The collapse of remoter communities is a threat that is amplified by the structural weaknesses brought about by poor economic infrastructure – they risk morphing into ‘museums of a past way of life’ with expensive holiday homes owned by significantly more wealthy outsiders, perhaps let out to vacationers and, maybe, a low-wage hospitality industry employing remaining local inhabitants.

Such a bleak outlook for local communities in remoter areas is by no means inevitable. Climate change imperatives are driving technological change and its adoption in energy generation and use. This is particularly true in the transportation sector, where aviation’s current contribution to CO2 emissions is significant and increasing.[10] General aviation, the ‘small aircraft category’, is set to be the first to embrace sustainability using green, electrical powertrain solutions – sustainable larger aircraft, by virtue of their size, will require longer in the development pipeline to achieve commercial introduction.

Electric general aviation aircraft with simpler powertrain components than current, conventionally fueled alternatives, combined with declining relative unit costs of green energy[11] offer the prospect for significantly reduced operating expenses.[12] Suitable configurations will provide excellent, short- to medium-haul transport solutions to enhance accessibility to, from, and within remoter communities. As a key to a viable green transport infrastructure, they are a very significant part of maintaining and reinvigorating remoter communities – beyond this there clearly must be the political will and determination from local and national government to see vibrant, diverse economies develop in these locations with the financial inputs and incentives necessary to deliver both sustainable, efficient, and effective physical (i.e. transport and logistics) and virtual (e.g., high-speed broadband) connectivity.

Being a robust, internally adaptable, externally reconfigurable, sustainable, electric general aviation solution, Cormorant is particularly well placed to meet the needs of communities based in remoter locations. This is no chance coincidence; it was conceived to deliver just such a transportation solution within its portfolio of potential roles.

[1] UN News (2014, September 21) FEATURE: no ‘Plan B’ for climate action as there is no ‘Planet B, says UN chief, https://news.un.org/en/story/2014/09/477962-feature-no-plan-b-climate-action-there-no-planet-b-says-un-chief – accessed 26/03/2022

[2] BBC News (2017, April 25) Macron to US Congress: ‘There is no Planet B,’ https://www.bbc.co.uk/news/av/world-us-canada-43900009 – accessed 26/03/2022

[3] For summary details, see https://www.unep.org/explore-topics/climate-action/facts-about-climate-emergency – accessed 26/03/2022

[4] Quotation by UN Secretary General, António Guterres, 23/09/2019, as at https://www.un.org/en/un75/climate-crisis-race-we-can-win, accessed 26/03/2022

[5] which originally appeared as “A l’exemple de Saturne, la révolution dévore ses enfants,” in a 1793 essay by Jacques Mallet du Pan, (1749-1800); Considérations sur la nature de la Révolution de France, et sur les causes qui en prolongent la durée.

[6] As at https://en.wikipedia.org/wiki/De_Havilland_Mosquito#Overview, accessed 26/03/2022

[7] As at https://www.srs.fs.usda.gov/pubs/misc/ag_654/volume_1/picea/sitchensis.htm, accessed 26/03/2022

[8] As at https://forest.jrc.ec.europa.eu/media/atlas/Picea_sitchensis.pdf, accessed 26/03/2022

[9] Minter, Steve (2014, February 7), Manufacturers Taking the Lead in the Circular Economy, IndustryWeek, https://www.industryweek.com/the-economy/media-gallery/21962277/manufacturers-taking-the-lead-in-the-circular-economy-slideshow – accessed 26/03/2022

[10] Overview of aviation sector; emissions, EASA, https://www.easa.europa.eu/eaer/topics/overview-aviation-sector/emissions – accessed 26/03/2022

[11] in article (June 22, 2021) Majority of New Renewables Undercut Cheapest Fossil Fuel on Cost. International Renewable Energy Agency, https://www.irena.org/newsroom/pressreleases/2021/Jun/Majority-of-New-Renewables-Undercut-Cheapest-Fossil-Fuel-on-Cost#:~:text=Renewable%20Power%20Generation%20Costs%20in,PV%20by%207%20per%20cent. Also. in respect of green hydrogen, in blogpost (January 19, 2022) Green hydrogen prices will plummet, catching out dithering investors, Ryze Hydrogen, https://ryzehydrogen.com/2022/01/19/green-hydrogen-prices-will-plummet/#:~:text=Rethink%20sees%20the%20cost%20of,Energy%20with%20%2410%20Trillion%20Spend.

[12] “Ganzarski says electric airplanes will be 40%-70% lower in cost to operate per flight hour.” – quotation in article (June 17, 2020) Electrifying the Industry, Aviation Pros, https://www.aviationpros.com/engines-components/aircraft-engines/electric-green-engine-technology/article/21139420/amt-junejuly-cover-story-going-green

Electric general aviation solutions will provide the first commercially available green aircraft solutions to reach the market. At Cormorant, it’s not just about producing a zero-CO2 emission aircraft – sustainability to us is more than that. Through setting sustainability as a goal from the outset, besides obviously producing a desirable, adaptable, reconfigurable aviation transport solution, we believe that Cormorant can contribute, albeit in a small part, to making the world a better place. Here we summarize how we see sustainability enriching both the communities served by our transport solution together with Cormorant’s stakeholder community, in terms of:

- Operating a zero-CO2 emission transport solution

- Use of sustainable materials in the structure of the aircraft

- Maximizing ‘circularity’

- Localizing value-added, where practical

- Distributed manufacturing

- Reinvigorating remoter communities

Zero-CO2 emission aviation transport

A primary driver for the renaissance currently underway in reduced- and zero-CO2 emission aviation transport solutions lies in the “There is no ‘planet B’” quotation attributed to the former UN Secretary General Ban Ki-moon[1] and memorably cited by French president Emmanuel Macron in an address to the US Congress.[2]Achieving zero-emission targets is about ‘deliverability,’ which we consider in this context to be making an effective, usable, certified, aviation transport solution that is ‘deliverable’ within the shortest timeframe. Adding unnecessary layers of complexity to concepts, particularly if they are technologically innovative, reduces speedy deliverability by encountering multiple, unnecessary bottlenecks, particularly in the regulatory certification process. Given the climate emergency,[3] speed is of the essence in delivering, viable sustainable solutions; now is perhaps not the time to be berating regulatory agencies charged with certifying these – particularly when their cultures are conservative, focused on incrementality, and have a justifiable preoccupation with safety.

We consider that incremental innovation and the use of proven, certified solutions where practical is the quickest and most responsible route to delivering green general aviation solutions. This leaves the regulatory framework relatively clear for the process of approval of zero-emission powertrains that are core to sustainable aviation solutions. We would contend that now is not the time to be grandstanding and, perhaps, massaging visionary egos by offering technologically overly radical, ‘sexy’ (in the marketing, presentational sense) projects to divert investors’ funds and regulators’ limited resources from achieving commercial, sustainable aviation solutions as soon as possible. The urgency of the climate emergency suggests that diversions from achieving the most demonstrably practical solutions are irresponsible; it “is a race we are losing, but it is a race we can win,”[4] but only through concerted focused effort and the avoidance of distractions.

Innovation not ‘total revolution’

We have previously considered the risks of over-promising and under-delivering when new aviation technology encounters the regulatory bottleneck that is the certification process.When a different technology is applied to meeting an existing market need, as is the case for zero-emission powertrains in aviation transport applications, there is a temptation to revolutionize rather than incrementally improve solutions.

Within a highly regulated sector, such as are aviation design, manufacturing, maintenance, training and operation, revolutionary solutions are anathema – particularly when ‘revolution’ occurs at multiple levels in offering an ‘exciting,’ exotic, new, integrated transport architecture. It is difficult enough for the certification authorities to approve new, “novel” powertrain solutions promptly and effectively for safe, commercial operation without adding layers of additional complication such as distributed power systems, autonomous flight, new air traffic control corridors, systems for urban aviation solutions etc.

Some exotic e-aviation solutions may well yield results, and we wish them and their investors well, for many however the quotation “like Saturn, the Revolution devours its children”[5] is likely to prove appropriate. ‘Exciting,’ new, overly revolutionary solutions can create a vortex of hubris for those vested in the project together with investors convinced of that project’s over-promises. Nemesis, in the form of those investors’ realization of under-delivery within their return timeframes, may unfortunately come all too swiftly.

Cormorant’s approach does not set out to be revolutionary. The use a zero-CO2 emission powertrain is the key technological step-change required to meet climate change limiting goals for aircraft operation, further use of ‘novel’ technologies elsewhere in the design serve only to frustrate and lengthen the certification process. Flexibility, both in terms of Cormorant’s utility for operators, and in its actual design, are central to offering a robust, multi-role, water- or land-surface operational aircraft that meets our original mission statement. Where a ‘revolutionary’ introduction of novel technology is required, i.e. in the design and installation of an electric powertrain, then our risk-minimizing, deferred strategic decision-making approach is a core management concept to keep our project focused and on-track.

Beyond this:

- ‘Evolution rather than [unnecessary] revolution’ is our maxim; we have incrementally improved several key design aspects to yield an electric, Short Take-Off & Landing (e-STOL) aircraft that is Cormorant – it addresses design and performance deficits in comparable current aircraft. This incremental approach and those projects that are retrofitting electric powertrains solutions within existing, certified airframes, are likely to produce practical, commercially usable solutions most quickly – this is what is needed in a time of climate crisis.

- We have revisited the use of proven, natural materials in the design, together with associated manufacturing processes upgraded to the 21st Building on others’ past achievements is sensible. ‘Reinventing the wheel’ when the planet needs solutions now is, to put it diplomatically, inappropriate.

We see Innovation not ‘total revolution’ as the most effective and efficient way to deliver a practical, robust, zero-emission aviation solution that meets our mission statement values within the shortest practical timeframe. The communities and stakeholders that rely on zero-emission transportation solutions to combat climate change, such as that which Cormorant offers, are depending on timely delivery – solution providers, such as us, cannot afford to disappoint.

Sustainable construction materials

Sustainability should not just relate to the consumers’ (or occupants’) day-to-day use of a product or service. For aircraft, it is not solely a consideration that they produce no climate impacting emissions when they are in flight; their manufacturing and decommissioning should also aim to be sustainable and circular as far as practicable. Minimal, ideally zero, environmental impact should be the aim.A significant contribution to sustainable manufacturing is Cormorant’s use of ecologically grown and harvested Sitka spruce as its core airframe material. A timber with an illustrious aviation heritage, Sitka spruce was a key structural component in, amongst others, the famous de Havilland Mosquito multirole combat aircraft, where the use of timber construction to facilitate “speed of prototyping, rapid development, minimization of jig-building time, and [subsequent] employment of a separate category of workforce”[6] hold true for Cormorant today.

Managed, sustainable cultivation and harvesting of this timber raw material occurs in several locations, including NW North America,[7] where Sitka spruce in endemic, and in northern Europe.[8]

Circularity

Circular manufacturing seeks to “reduce the use of materials and energy in manufacturing products and services and then recover as much of the end products as possible through reuse and recycling.”[9]Whilst the use of timber as a principal raw material in Cormorant’s airframe does not confer circularity per se, the use of such sustainable grown, harvested, and processed material combined with a circular philosophy applied to other components (i.e., within the aircraft’s powertrain, avionics, and other systems) results in a minimalist approach to the environmental impact of manufacturing. We shall not only produce an operationally zero-emission aircraft but will also aim to leave the smallest imprint practically possible.

Localizing value-added

Sustainability does not start and stop with the operation of an aircraft and the manufacturing and decommissioning processes that produce and recycle it. It is also about the sharing of prosperity throughout the chain of value-added in the economic cycle.This is rather a verbose way of saying that we believe, where feasible and practical, the benefits of a successful project should be distributed fairly amongst its stakeholders. For example, if timber raw material is produced on the lands of an indigenous community, then thoughtful consideration should be focused on adding value within that supplier stakeholder group, e.g., through further processing of raw materials and / or sub-contract the manufacturing of components.

We do not believe that localizing value-added is altruism for its own sake. Rather, it is a key component of a broader sustainable philosophy. Enhanced involvement of stakeholders, particularly suppliers in vulnerable or often-bypassed communities, can help their economic empowerment and contribute to their social sustainability.

Localization of value-added, as a concept, also feeds into the concept of distributed manufacturing.

Distributed manufacturing

At Cormorant, we do not foresee the requirement for expensive molds and other costly tooling as part of the aircraft production process, which would require the centralization of manufacturing operations in one principal site in which to concentrate capital investment. This, combined with the aircraft’s principally wooden, weight-saving, monocoque airframe, results in simplified production processes and optimized construction time.Such a design and manufacturing process enables aircraft production to be, within reason, ‘distributed.’ Where volumes justify establishment, production sites could be located to serve key geographic market areas to perform aircraft assembly and serve distribution networks for finished aircraft, spare parts, and equipment more locally.

Reinvigorating remoter communities

Above, we briefly discussed how localizing value-added can assist in helping empower vulnerable or bypassed communities that may support our supply chain. Here we consider some of several roles that can be fulfilled by Cormorant in serving the transportation needs of remoter communities, which are often poorly served by any existing infrastructure. Our affordable, sustainable, practical transport solution have the potential to help sustain and invigorate remoter communities whether they are end-users of the Cormorant aircraft or are a key component within its supply chain.Due to poor infrastructure, particularly poor transport infrastructure, remoter communities can often suffer from selective depopulation of their younger inhabitants such that their demographics become increasingly elderly to the point of economic and social non-sustainability. Social infrastructure can easily degrade over time: schools may close due to there being insufficient pupils or professional staff proving difficult to recruit; medical facilities may also relocate to centers of higher population density; traditional businesses may become unviable and close; and / or second- holiday-home ownership from wealthy outsiders, attracted to the remoteness, may perversely inflate housing prices making them unaffordable for those ‘locals’ who wish to remain. The collapse of remoter communities is a threat that is amplified by the structural weaknesses brought about by poor economic infrastructure – they risk morphing into ‘museums of a past way of life’ with expensive holiday homes owned by significantly more wealthy outsiders, perhaps let out to vacationers and, maybe, a low-wage hospitality industry employing remaining local inhabitants.

Such a bleak outlook for local communities in remoter areas is by no means inevitable. Climate change imperatives are driving technological change and its adoption in energy generation and use. This is particularly true in the transportation sector, where aviation’s current contribution to CO2 emissions is significant and increasing.[10] General aviation, the ‘small aircraft category’, is set to be the first to embrace sustainability using green, electrical powertrain solutions – sustainable larger aircraft, by virtue of their size, will require longer in the development pipeline to achieve commercial introduction.

Electric general aviation aircraft with simpler powertrain components than current, conventionally fueled alternatives, combined with declining relative unit costs of green energy[11] offer the prospect for significantly reduced operating expenses.[12] Suitable configurations will provide excellent, short- to medium-haul transport solutions to enhance accessibility to, from, and within remoter communities. As a key to a viable green transport infrastructure, they are a very significant part of maintaining and reinvigorating remoter communities – beyond this there clearly must be the political will and determination from local and national government to see vibrant, diverse economies develop in these locations with the financial inputs and incentives necessary to deliver both sustainable, efficient, and effective physical (i.e. transport and logistics) and virtual (e.g., high-speed broadband) connectivity.

Being a robust, internally adaptable, externally reconfigurable, sustainable, electric general aviation solution, Cormorant is particularly well placed to meet the needs of communities based in remoter locations. This is no chance coincidence; it was conceived to deliver just such a transportation solution within its portfolio of potential roles.

[1] UN News (2014, September 21) FEATURE: no ‘Plan B’ for climate action as there is no ‘Planet B, says UN chief, https://news.un.org/en/story/2014/09/477962-feature-no-plan-b-climate-action-there-no-planet-b-says-un-chief – accessed 26/03/2022

[2] BBC News (2017, April 25) Macron to US Congress: ‘There is no Planet B,’ https://www.bbc.co.uk/news/av/world-us-canada-43900009 – accessed 26/03/2022

[3] For summary details, see https://www.unep.org/explore-topics/climate-action/facts-about-climate-emergency – accessed 26/03/2022

[4] Quotation by UN Secretary General, António Guterres, 23/09/2019, as at https://www.un.org/en/un75/climate-crisis-race-we-can-win, accessed 26/03/2022

[5] which originally appeared as “A l’exemple de Saturne, la révolution dévore ses enfants,” in a 1793 essay by Jacques Mallet du Pan, (1749-1800); Considérations sur la nature de la Révolution de France, et sur les causes qui en prolongent la durée.

[6] As at https://en.wikipedia.org/wiki/De_Havilland_Mosquito#Overview, accessed 26/03/2022

[7] As at https://www.srs.fs.usda.gov/pubs/misc/ag_654/volume_1/picea/sitchensis.htm, accessed 26/03/2022

[8] As at https://forest.jrc.ec.europa.eu/media/atlas/Picea_sitchensis.pdf, accessed 26/03/2022

[9] Minter, Steve (2014, February 7), Manufacturers Taking the Lead in the Circular Economy, IndustryWeek, https://www.industryweek.com/the-economy/media-gallery/21962277/manufacturers-taking-the-lead-in-the-circular-economy-slideshow – accessed 26/03/2022

[10] Overview of aviation sector; emissions, EASA, https://www.easa.europa.eu/eaer/topics/overview-aviation-sector/emissions – accessed 26/03/2022

[11] in article (June 22, 2021) Majority of New Renewables Undercut Cheapest Fossil Fuel on Cost. International Renewable Energy Agency, https://www.irena.org/newsroom/pressreleases/2021/Jun/Majority-of-New-Renewables-Undercut-Cheapest-Fossil-Fuel-on-Cost#:~:text=Renewable%20Power%20Generation%20Costs%20in,PV%20by%207%20per%20cent. Also. in respect of green hydrogen, in blogpost (January 19, 2022) Green hydrogen prices will plummet, catching out dithering investors, Ryze Hydrogen, https://ryzehydrogen.com/2022/01/19/green-hydrogen-prices-will-plummet/#:~:text=Rethink%20sees%20the%20cost%20of,Energy%20with%20%2410%20Trillion%20Spend.

[12] “Ganzarski says electric airplanes will be 40%-70% lower in cost to operate per flight hour.” – quotation in article (June 17, 2020) Electrifying the Industry, Aviation Pros, https://www.aviationpros.com/engines-components/aircraft-engines/electric-green-engine-technology/article/21139420/amt-junejuly-cover-story-going-green

Share this: